In the fast-paced world of electronics, innovation and efficiency go hand in hand. One of the biggest game-changers? Surface Mount Assembly (SMA). Whether you’re a tech startup, a hobbyist, or a large-scale manufacturer, SMA is the go-to method for assembling compact, high-performance electronic devices. Let’s break down why this technique is a must-have in your toolbox.

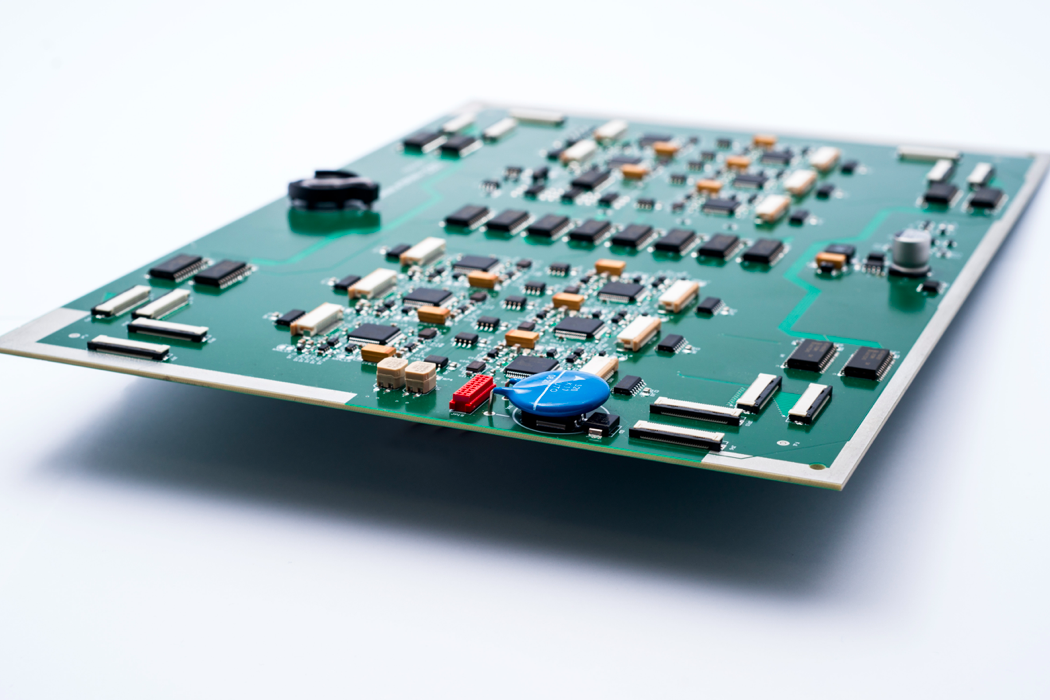

1. Compact Design for Space-Saving Efficiency

Thanks to Surface Mount Assembly, components can be placed directly onto the surface of a PCB, eliminating the need for long leads or bulky mounting holes. The result? Sleek, compact boards that are ideal for space-limited projects like smartphones, wearables, and IoT devices.

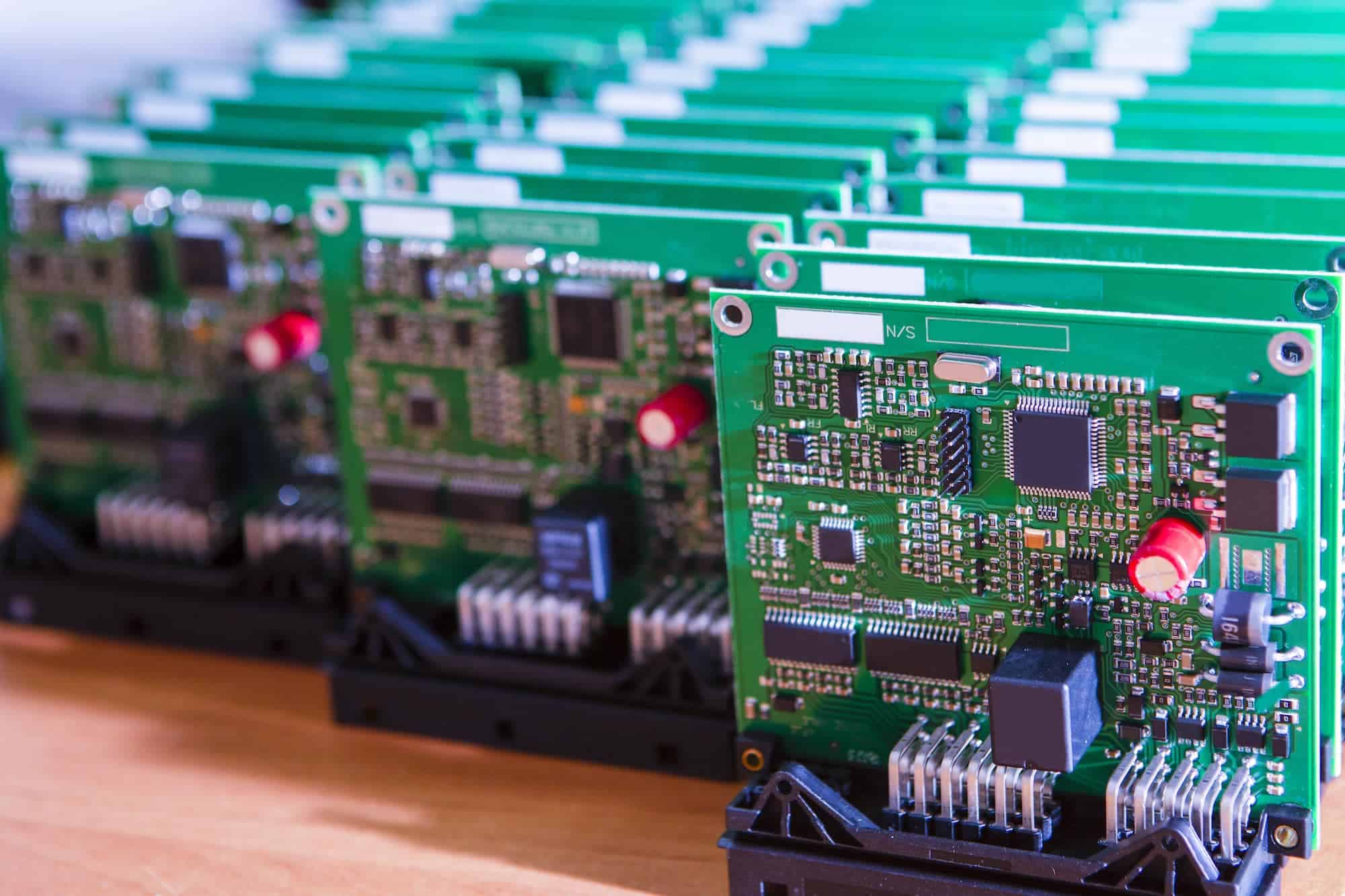

2. Faster Production Time

No one likes waiting. Luckily, SMA speeds up assembly like a dream. Its automation-friendly nature means components are placed and soldered in bulk, cutting down production time significantly and getting your product to market faster.

3. Reduced Manufacturing Costs

Less labor, smaller boards, and quicker turnaround times? That adds up to serious savings. Surface Mount Assembly reduces overall manufacturing costs while increasing output, which is a win-win!

4. Enhanced Performance and Reliability

Shorter paths between components mean lower resistance and inductance. Translation: your circuits perform better and are less likely to experience electrical noise or signal delays. That’s top-tier reliability for critical applications.

5. Double-Sided PCB Assembly

Here’s a cool feature: SMA allows for double-sided PCB population. That means more components packed into smaller spaces, giving you design flexibility without compromising on power or functionality.

6. Stronger Mechanical Bonding

SMA isn’t just about speed. It’s also about strength. Components are soldered directly to the board, giving them greater resistance to vibrations and mechanical stress. Think rugged devices or industrial tools that need to endure tough conditions.

7. Ideal for High-Density Applications

Trying to fit more tech into tighter spaces? Surface Mount Assembly is your best friend. It’s the preferred choice for high-density boards where performance and miniaturization are non-negotiable.

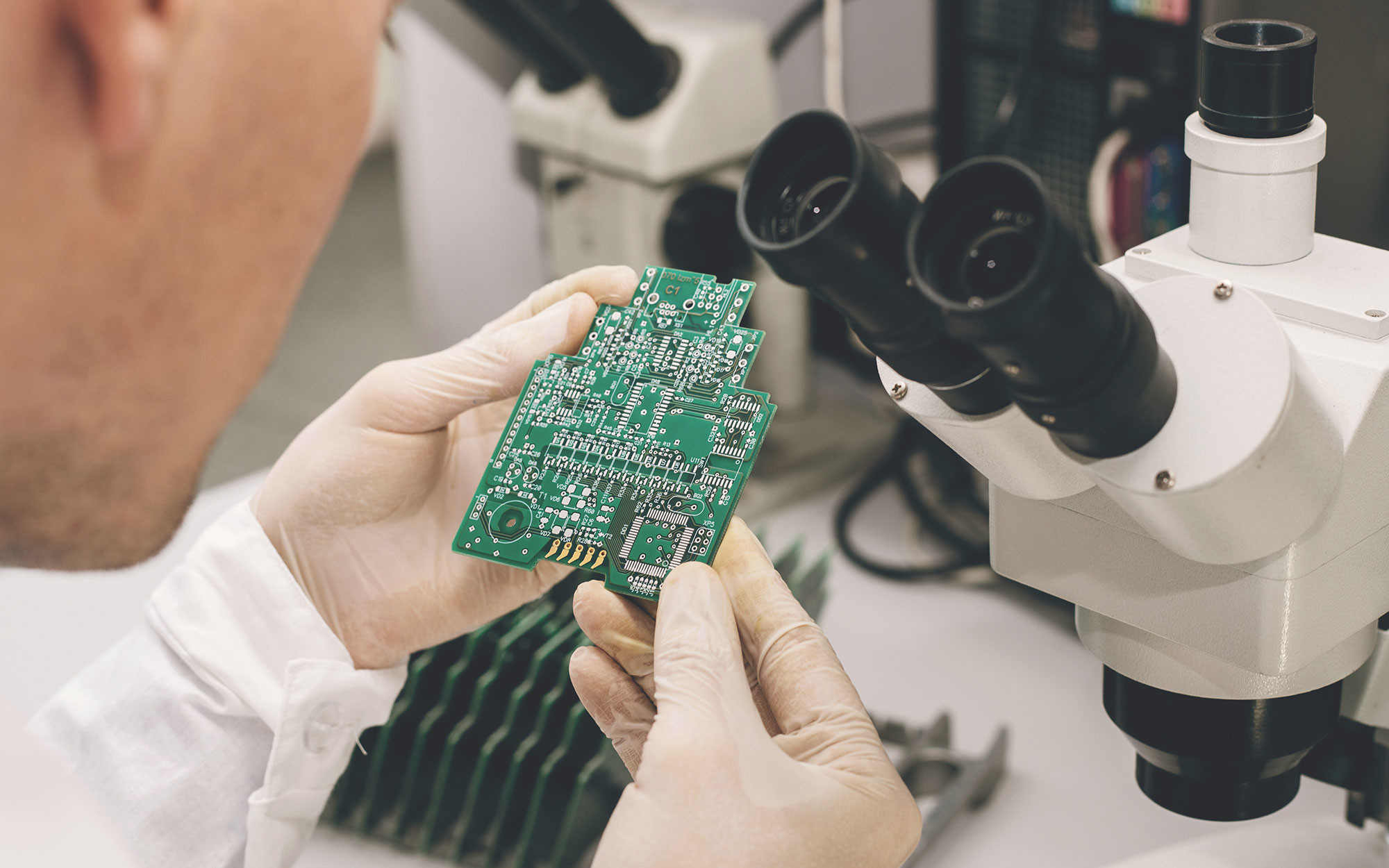

8. Simplified Prototyping and Testing

With the rise of advanced software and pick-and-place machines, designing, prototyping, and testing SMA-based circuits has become more streamlined than ever. Iterate fast, test easily, and get ready to launch confidently.

9. Better Thermal Performance

SMA components are generally smaller, which means better heat dissipation. Plus, using thermal vias and heatsinks on PCBs with surface-mounted parts helps manage thermal loads more effectively.

10. Eco-Friendly and Future-Ready

Less material waste, minimal lead usage, and leaner designs make Surface Mount Assembly an eco-conscious choice. As sustainability becomes a priority in electronics, SMA is already leading the charge.

Conclusion

When it comes to efficient, reliable, and cost-effective electronics manufacturing, Surface Mount Assembly checks all the boxes. Whether you are aiming to create cutting-edge gadgets or streamline your production process, this technique gives you the flexibility, performance, and quality your projects need.

So, if you’re not already using SMA, it’s time to plug into the future!

FAQs

- What is Surface Mount Assembly in simple terms?

It’s a method where components are mounted directly onto the surface of PCBs, unlike older techniques that use holes and wires. - Can I use SMA for small DIY electronics?

Absolutely! SMA is great for compact DIY projects and is supported by many modern PCB design tools. - Is SMA more expensive than traditional methods?

Initially, it may require a setup investment, but over time, SMA is more cost-effective due to automation and reduced labor. - Are SMA components easy to replace?

While small, many SMA components can be replaced using hot air rework stations and proper tools. - Why is SMA better for high-speed circuits?

It shortens the electrical path, reducing signal loss, making it ideal for high-frequency, high-speed applications.