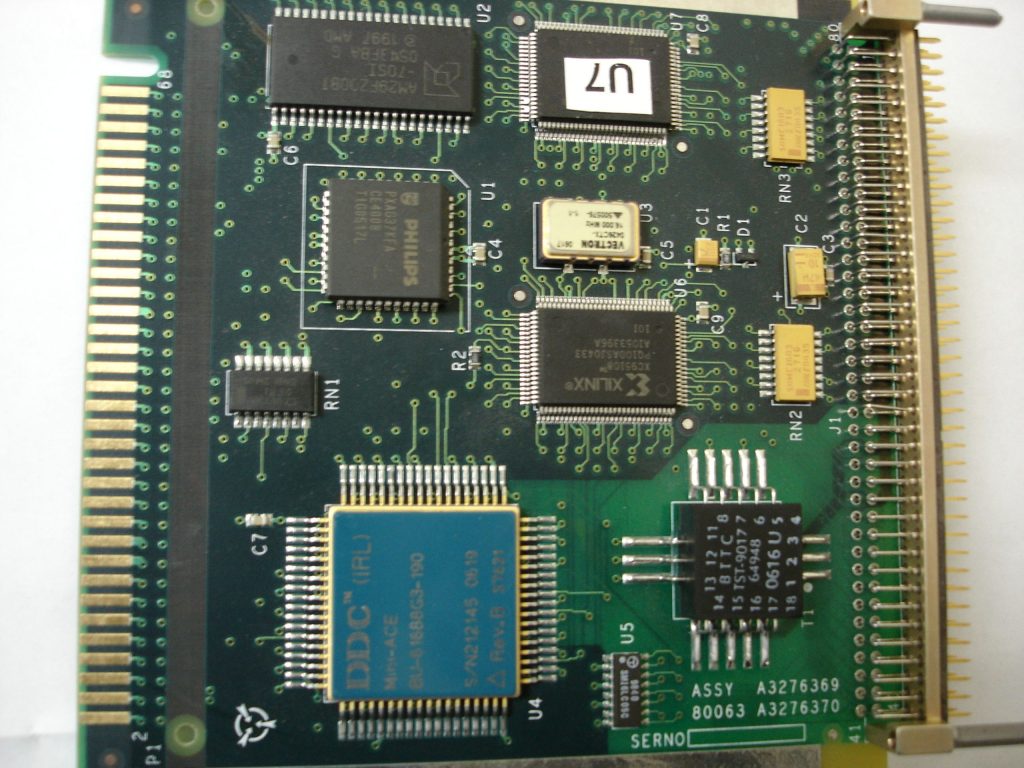

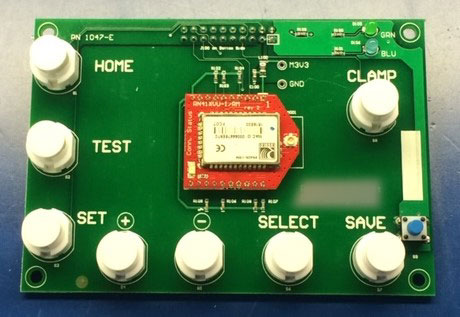

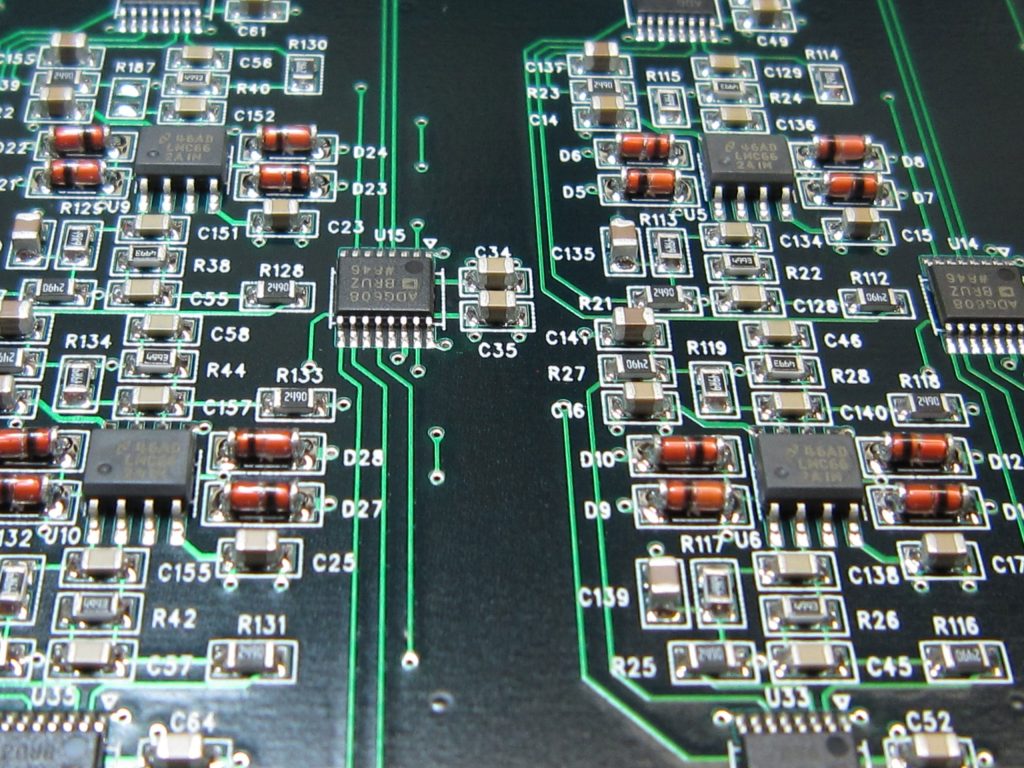

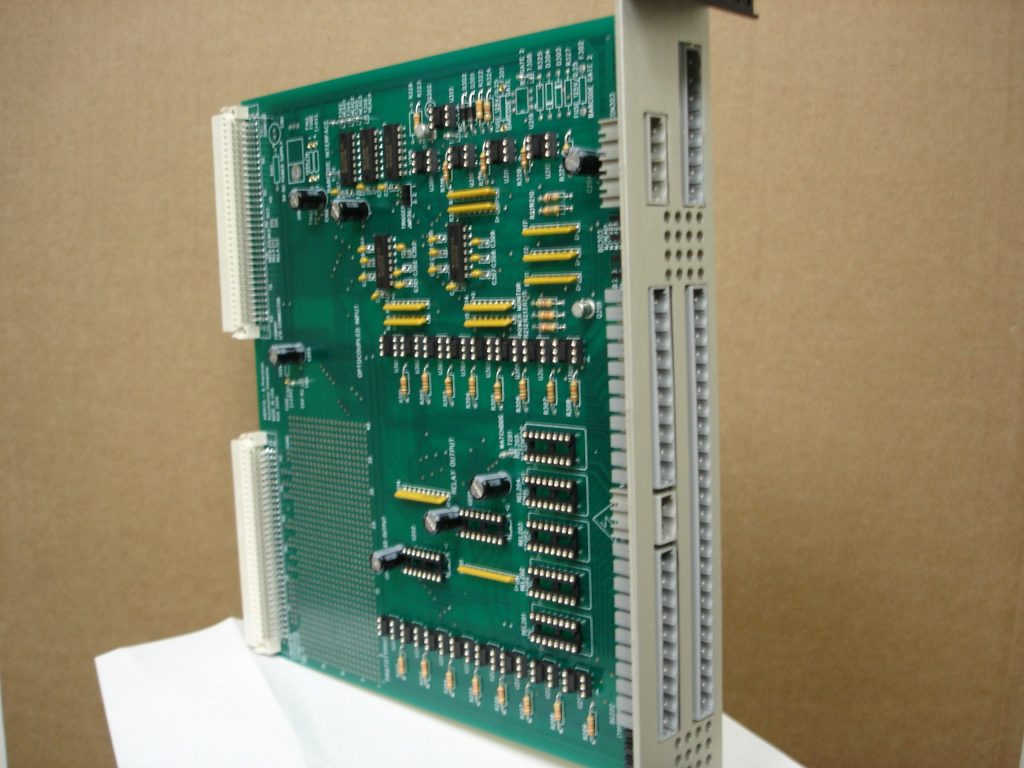

Surface mount technology is the process where the electronic components are assembled by the automated machines directly on the surface of the printed circuit board. This allows for increased manufacturing automation which reduces cost and improves quality. This is the most frequently used technology.

We will review your files to ensure your product is designed for manufacturability, eliminating unnecessary costs in the process.

Eii can easily fulfill your quick turn PCB Assembly needs. Whenever you need fast, low-volume or prototype printed circuit board assemblies you can count on us.

We provide lead-free printed circuit boards assembly services for your applications. Our procurement team ensures that all the components sourced for lead-free assembly are free from hazardous substances.. We use halogen free boards, FR4 materials that are RoHS complaint, high temperature Tg and Td materials, lead free e solder paste in the assembly process.

The boards finish should be either Lead-free Solder Finish (lead-free HASL)or Electroless Nickel Immersion Gold (ENIG)or Immersion Silver Electroplated Nickel and Soft (bondable) and Hard Gold Immersion Tin (White Tin) or Organic Solderability Preservatives (OSP).

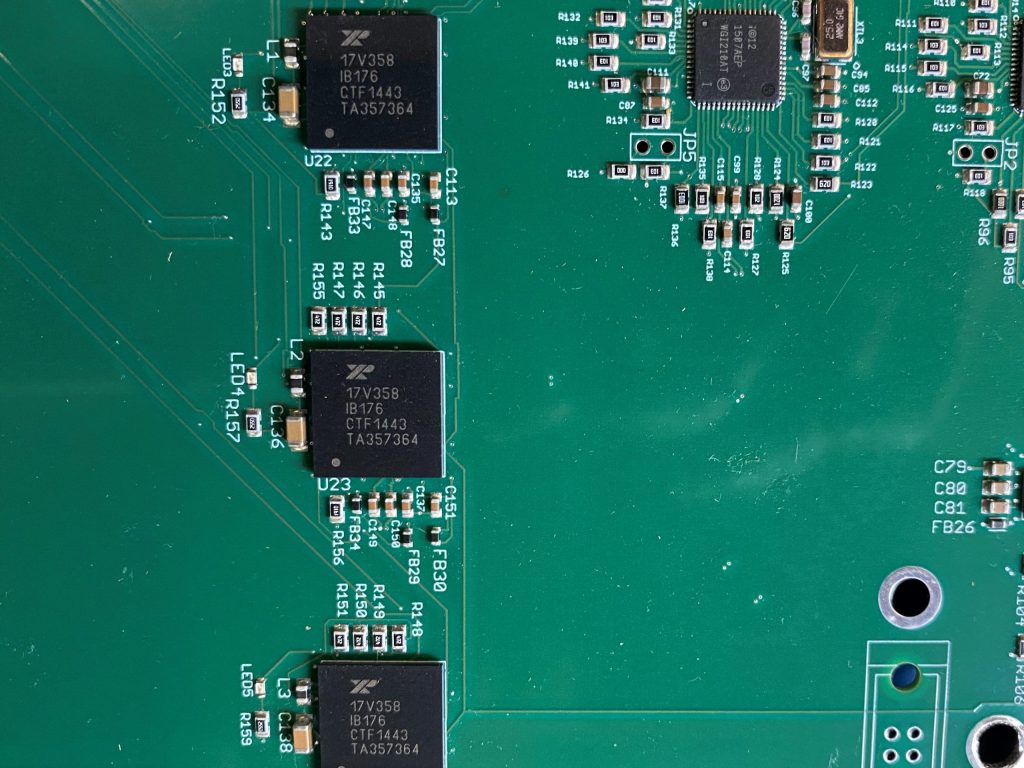

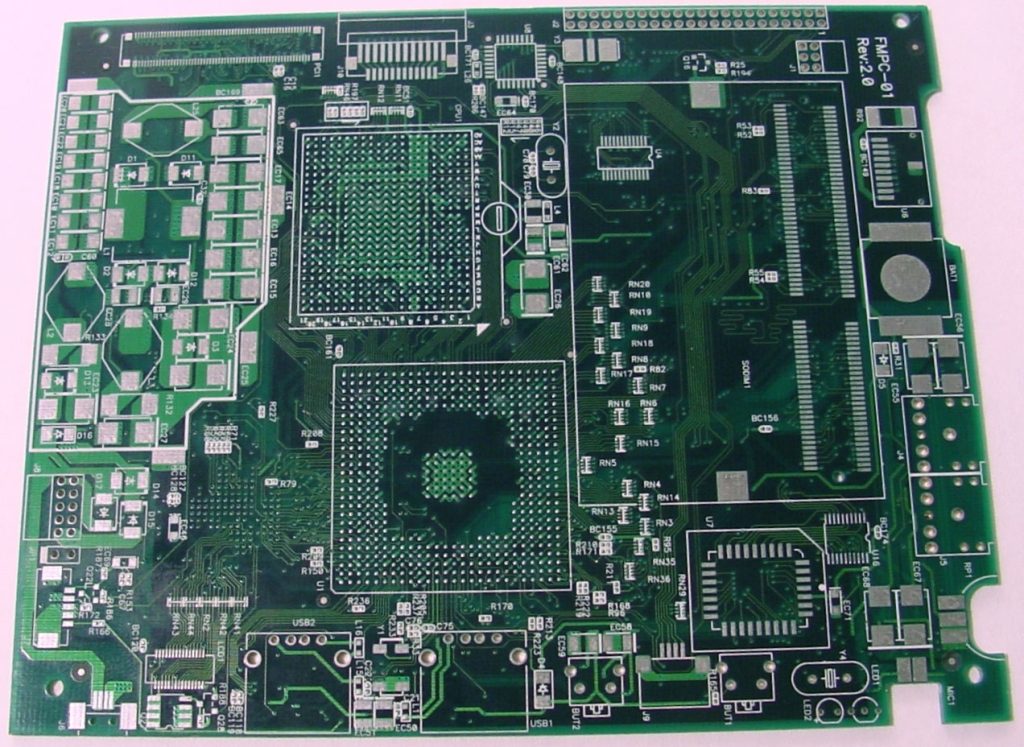

BGA is an advanced packaging technology in SMT assembly. A Ball Grid Array Integrated Circuit is a surface mount device (SMD) component that possesses no leads. This SMD package employs an array of metal spheres that are made of solder called the solder balls for connections to the PCB (Printed Circuit Board).

For BGA soldering, the solder balls on the package have a very carefully controlled amount of solder, and when heated in the soldering process, the solder melts. Surface tension causes the molten solder to hold the package in the correct alignment with the circuit board, while the solder cools and solidifies

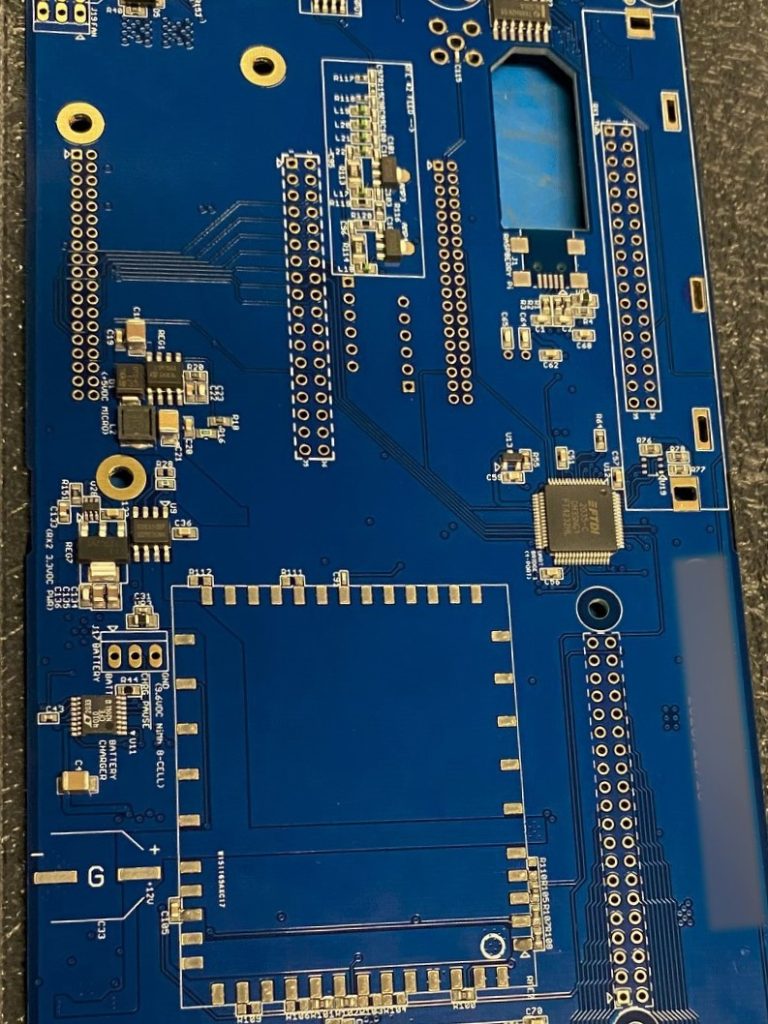

For rework and modification, we provide refinishing operations or repair of an electronic printed circuit board (PCB) assembly, usually involving desoldering and re-soldering of surface-mounted electronic components (SMD).

Apart from these, we can also provide rework and reballing services for BGAs that are already in use. Our rework and reballing capabilities include BGA removal and replacement, rework of ceramic and plastic BGAs and reballing of MBGAs. Our rework system comprises of:

Fineline Circuits Inc, our sister company, has over 27 years of manufacturing printed circuit boards experience. All process are done in-house at our Feasterville location.

© Copyright 2021 Electronic Integration Inc All rights reserved