The trend toward greater and greater electronic miniaturization and wearable electronics (PCB + electricity + sweat = problems) has led to a higher demand for the protection and reliability offered by conformal coating

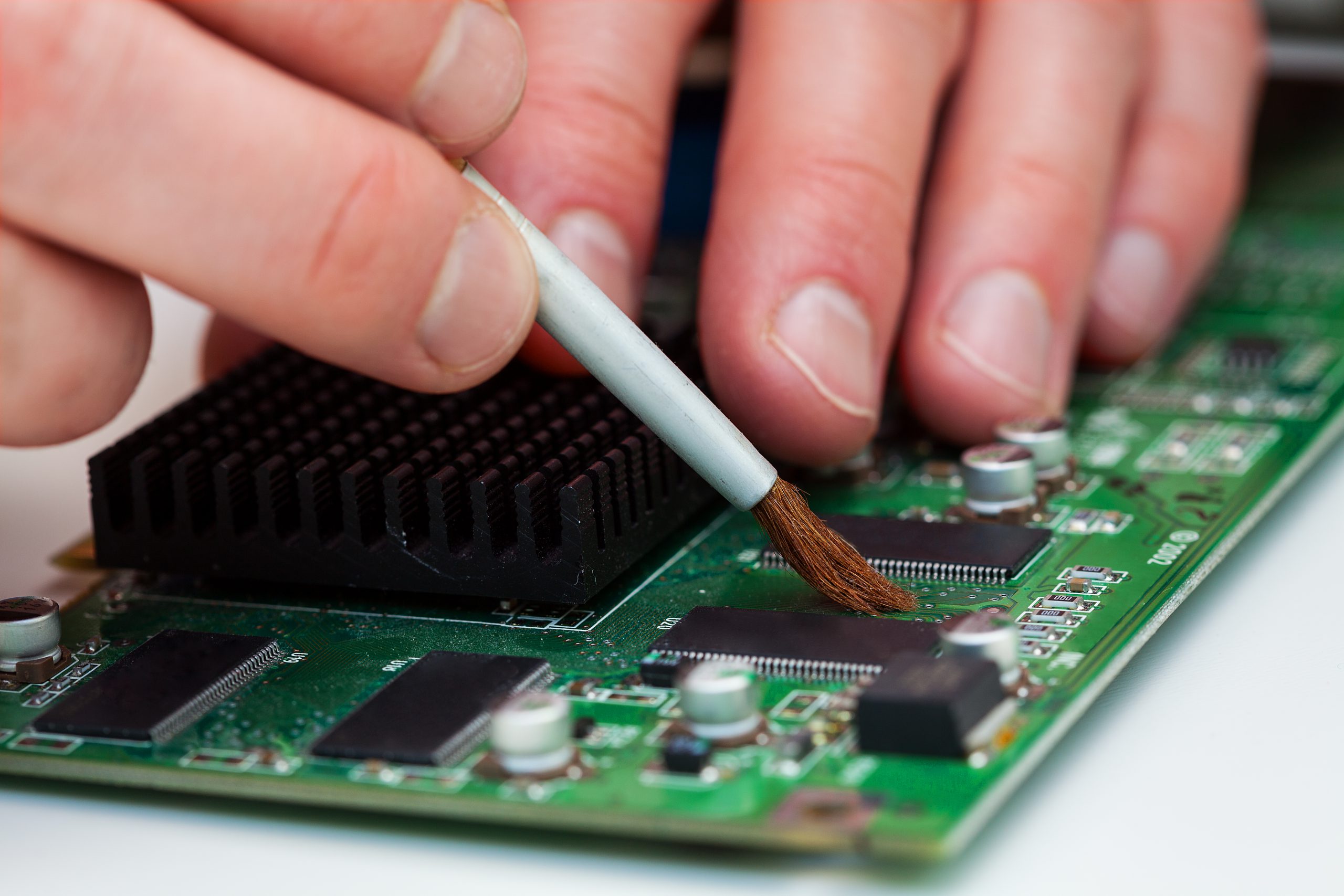

Conformal Coating is a polymeric film producing coating that protect the underlying circuits and components and devices from other adverse environment conditions like dust, moisture, corrosion, thermal shock, and vibration. This is done by coating the board with a layer of transparent polymeric film. It covers and conforms to the circuit board topography. This can be applied either by spray, dip or brush method depending upon customer requirements.

We use Acrylic, Urethane and Silicone products with UV indicators for quality control. Here is a list of common products used in the conformal coating process:

We can help you with your requirements. We are ISO9001-2015 certified. We uphold to IPC standards for both performance(IPC 6012) and acceptability IPC-A-610 class 2 and class 3 for pcbs. We have Certified IPC trainer and solderers, are ROHAS, REACH and conflict material compliant, EPA,FAR and NAFTA, compliant.