Introduction to Prototype PCB Manufacturing

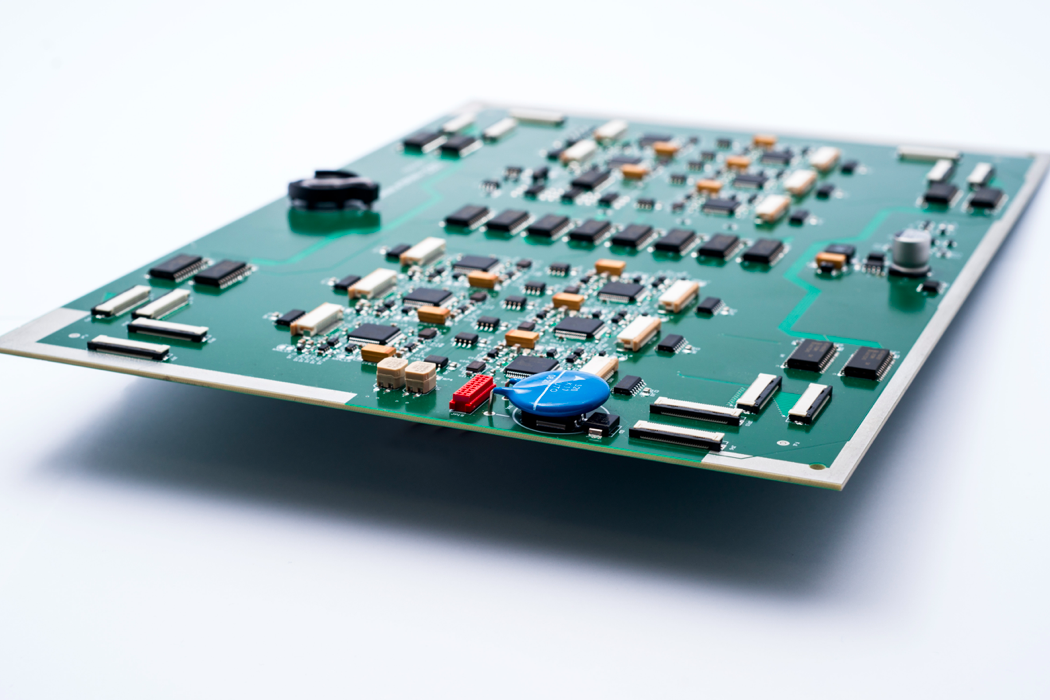

Prototype PCB manufacturing is the foundation of innovation in electronics. It’s the process of designing and producing sample circuit boards to test and validate designs before full-scale production. Whether you’re creating next-gen wearables or medical devices, prototype PCBs bring your ideas to life.

The keyword prototype PCB manufacturing isn’t just a tech buzzword, it’s a critical part of the electronics development lifecycle.

Why Choosing the Right Manufacturer Matters

Choosing the wrong manufacturer can derail your entire project. Delays, miscommunication, and low-quality boards can cost time, money, and market opportunities.

Costly Mistakes from Poor PCB Prototyping

- Misaligned layers

- Incorrect component footprints

- Poor soldering quality

- Incompatible materials

Each of these issues can lead to product failure or expensive rework.

Key Traits of a Top-Tier Prototype PCB Manufacturer

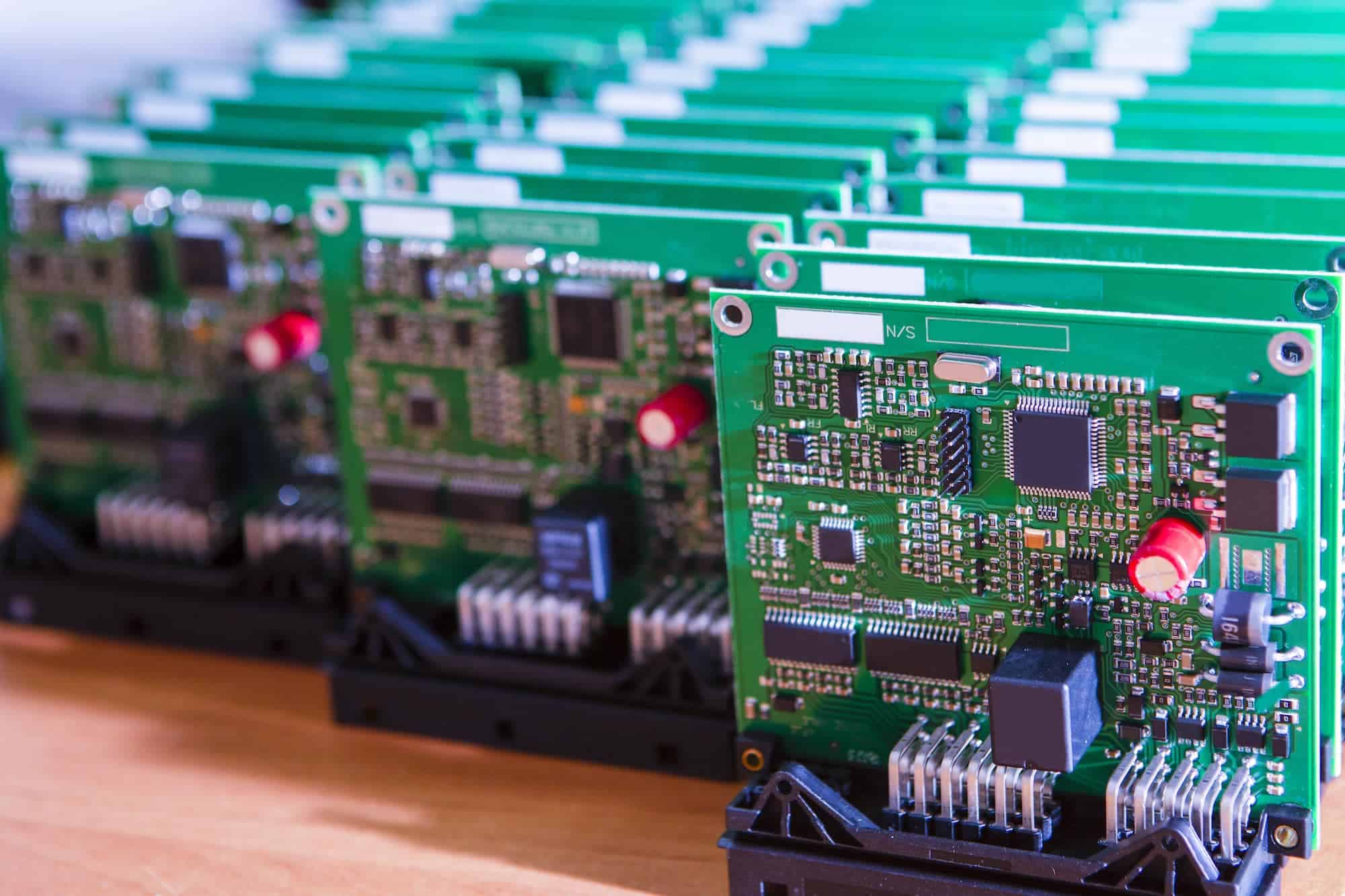

1. Speedy Turnaround Times

A top manufacturer delivers quick prototyping without compromising quality. Time-to-market can make or break a product’s success.

2. Advanced Manufacturing Technology

From laser drilling to HDI techniques, modern tools ensure accuracy and scalability.

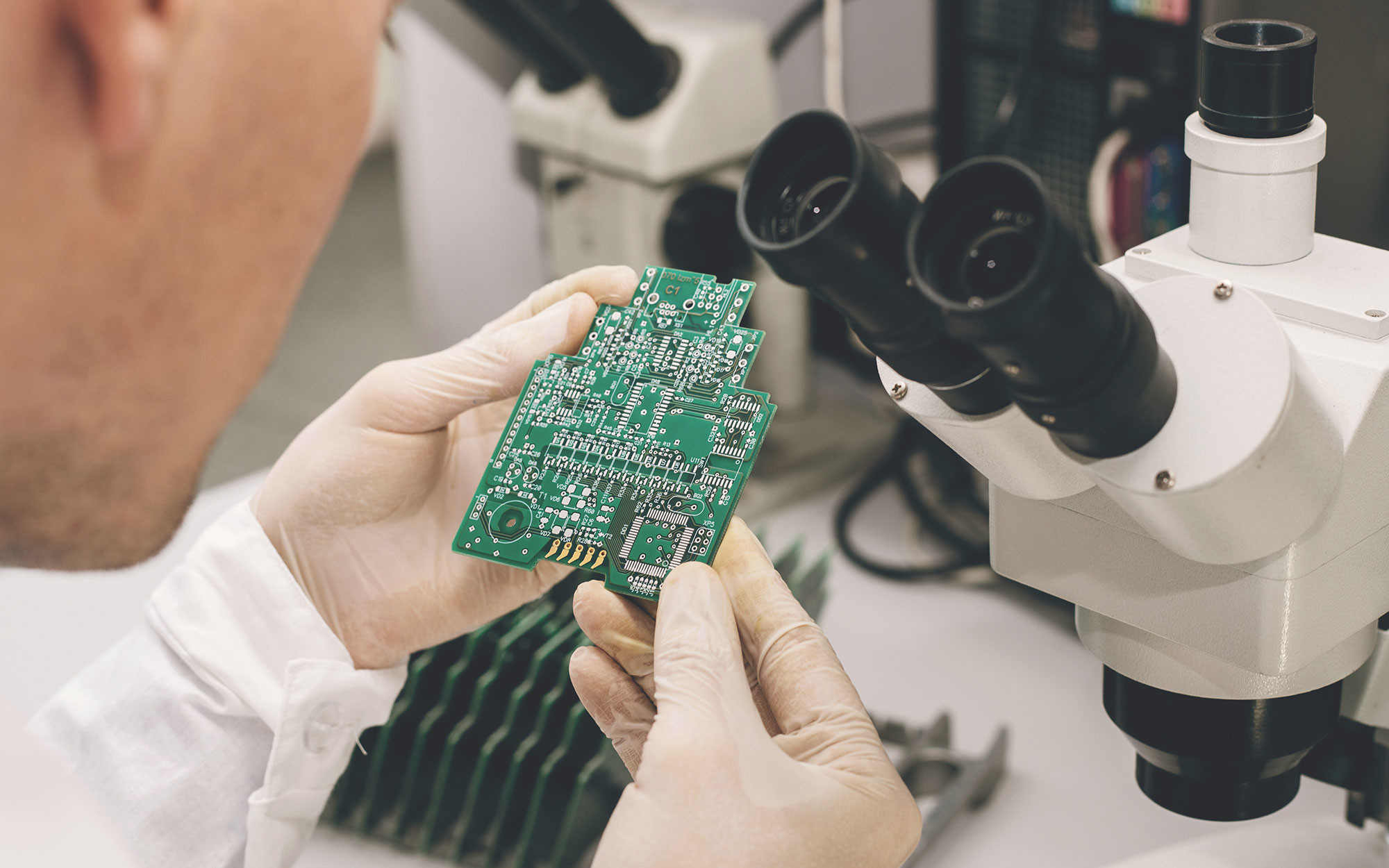

3. Precision & Quality Assurance

Look for strict testing procedures:

- AOI (Automated Optical Inspection)

- Flying probe testing

- X-ray inspection

4. Expert Engineering Support

Skilled engineers can spot design flaws early and recommend improvements.

5. Transparent Communication

Clear updates, real-time tracking, and consistent feedback loops are non-negotiable.

How to Evaluate a Manufacturer’s Capabilities

Questions to Ask Before Partnering

- What’s your average lead time for prototypes?

- Can you provide references or case studies?

- What certifications do you hold?

Certifications That Matter

- ISO 9001

- IPC standards

- RoHS compliance

These aren’t just badges. They are proof of quality control and environmental responsibility.

Industries That Rely on Prototype PCB Manufacturing

Aerospace

High-performance and mission-critical systems demand precision.

Medical Devices

Miniaturization and reliability are key, and errors aren’t an option.

Consumer Electronics

Smartwatches, phones, and home gadgets all go through rigorous prototyping.

Common Challenges in PCB Prototyping

- Miscommunication between design and fabrication

- Incomplete Gerber files

- Material selection mismatches

- Budget constraints

Partnering with the right manufacturer helps navigate these hurdles with ease.

FAQs

What is prototype PCB manufacturing?

It’s the process of creating initial samples of circuit boards to validate design and functionality before full production.

Why is quick turnaround important in PCB prototyping?

It allows faster testing and development cycles, helping you beat competitors in the market.

How do I know if a manufacturer is reliable?

Check for industry certifications, customer reviews, and responsiveness during inquiries.

What are the common materials used in PCB prototypes?

FR4, polyimide, Rogers, and other materials, depending on thermal and electrical requirements.

Is prototype PCB manufacturing expensive?

Costs vary based on complexity, turnaround time, and materials, but it’s a crucial investment in your product’s success.

Can I modify my design after the prototype is made?

Yes, and it’s common. That’s why rapid prototyping is invaluable, it allows for revisions before mass production.

Conclusion

In the fast-paced world of electronics, your choice in a prototype PCB manufacturing partner can define your project’s outcome. Speed, quality, support, and transparency set the great ones apart. Do your homework, ask the right questions, and never settle for less than exceptional.

Looking for reliable prototype PCB manufacturing? Visit Electronic Integration INC, where precision meets performance.