Introduction to SMT Manufacturing in 2025

Surface Mount Technology (SMT) manufacturing is entering a new era in 2025. Fueled by groundbreaking innovations, automation, and artificial intelligence (AI), SMT production is achieving unprecedented levels of efficiency, precision, and sustainability. With everything from AI-powered inspection systems to eco-friendly manufacturing processes, this year marks a significant turning point in the electronics production industry.

Let’s take a closer look at the top 10 innovations reshaping SMT production lines globally.

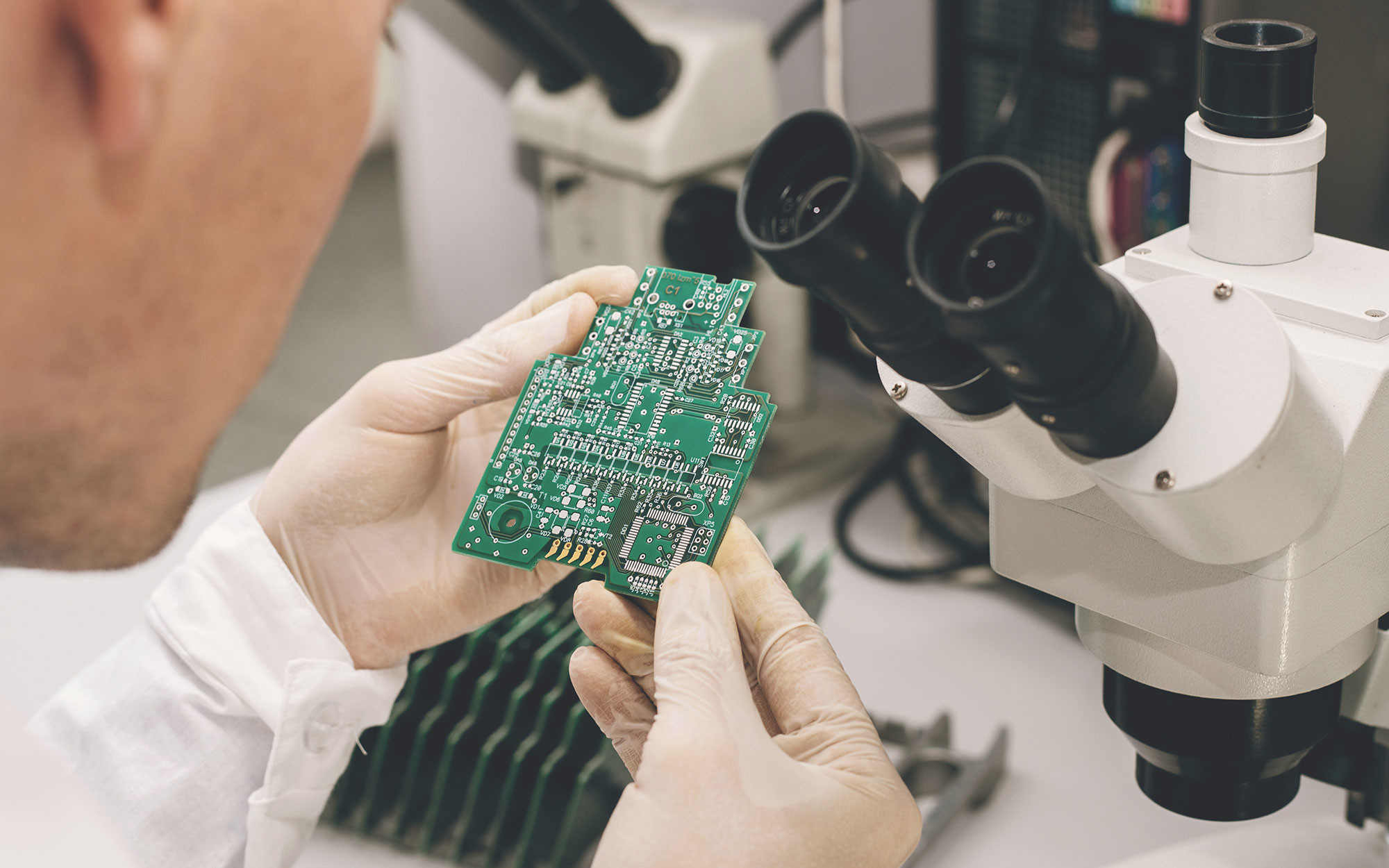

1. AI-Driven Quality Control

Machine learning is eliminating the guesswork in quality control. By 2025, AI-based systems will detect defects faster and more accurately than ever before.

How AI is Improving SMT Inspection

- Defect detection: Spotting issues like misalignments, soldering errors, and missing parts in mere milliseconds.

- Pattern recognition: AI learns from previous errors to continuously refine its inspection processes.

- Adaptive systems: Systems adjust inspection parameters in real time to accommodate product variations.

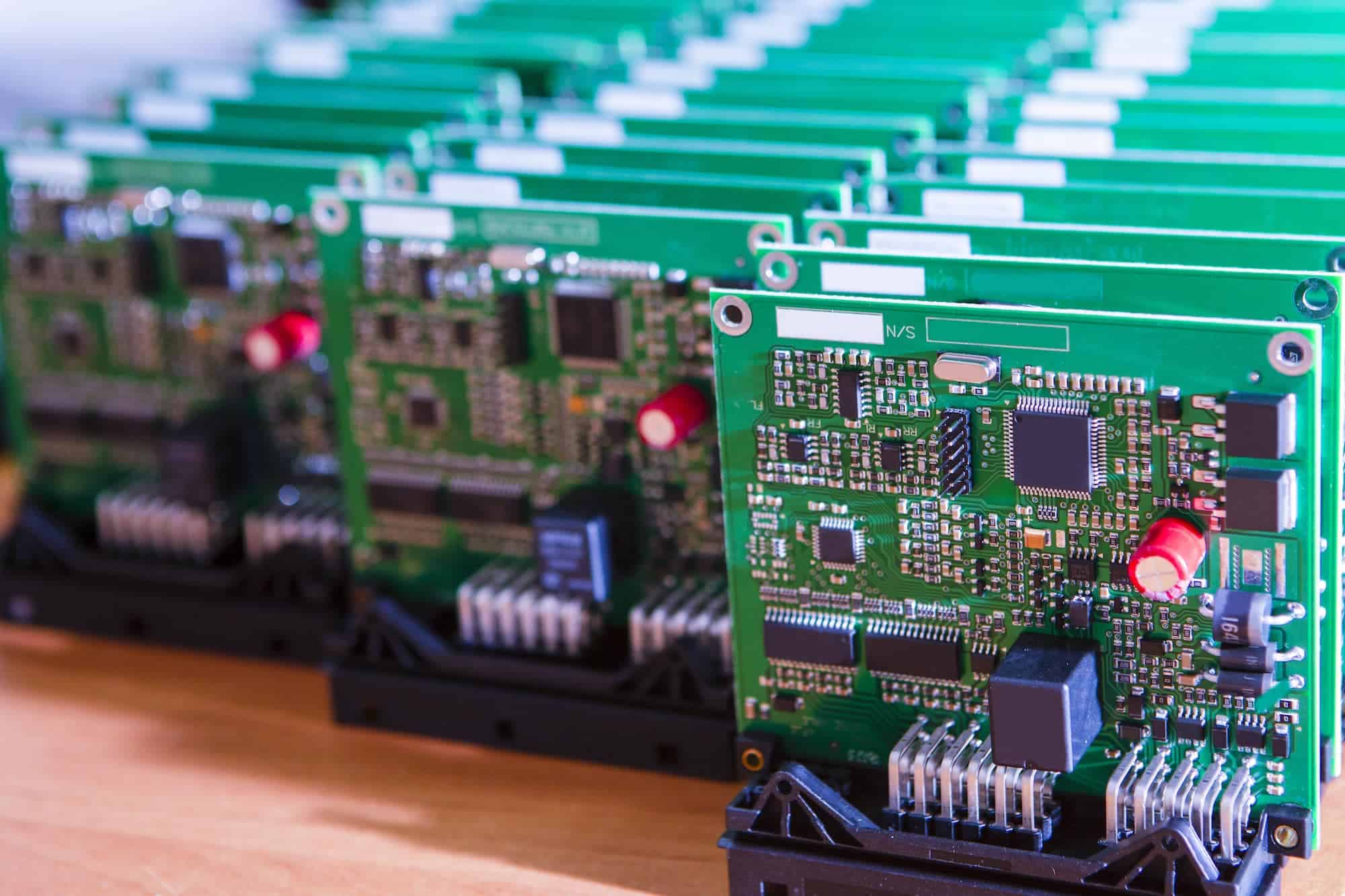

2. Smart Factory Integration

Smart factories are no longer just a vision for the future, and they are here now. SMT manufacturing thrives with seamless communication between machines and systems.

The Role of IoT in SMT Systems

- Sensors and connectivity enable real-time machine communication.

- Remote monitoring enhances reaction times when machines encounter issues.

- Data automation improves efficiency across production lines.

3. Real-Time Data Analytics

In 2025, data is more than just numbers; it’s invaluable insight. Real-time analytics allow SMT manufacturers to predict equipment failures before they occur.

Benefits of Predictive Maintenance

- Reduce downtime by catching wear and tear early.

- Allocate maintenance teams more efficiently.

- Increase throughput by preventing unexpected breakdowns.

4. Advances in Automated Optical Inspection (AOI)

AOI systems in 2025 are faster, smarter, and more reliable, thanks to deep learning.

AI and AOI: A Perfect Pairing

- Precise inspection with minimal manual involvement.

- Real-time feedback to upstream processes.

- Higher yields and fewer defects.

5. Miniaturization & Component Density

Electronics are shrinking, and so are the components in SMT.

Overcoming Challenges with Microelectronics

- Advanced placement machines now handle components as small as <01005.

- High-accuracy soldering tackles increasingly tight footprints.

- Innovative adhesives and solders provide stronger bonds.

6. Robotic Soldering & Pick-and-Place Machines

he rise of cobots (collaborative robots) is accelerating the pace of SMT automation.

Speed + Precision = Future of Assembly

- Pick-and-place machines now achieve speeds of up to 150,000 components per hour.

- Consistent soldering eliminates human error.

- 24/7 production with minimal supervision.

7. Training & Troubleshooting Using Augmented Reality (AR)

Training new technicians has received an upgrade. AR is helping staff learn faster and more effectively.

AR in Action on the SMT Floor

- Step-by-step guides are overlaid in real time.

- Live diagnostics are shown via AR glasses.

- Reduced training hours and improved retention rates.

8. Green Manufacturing Solutions

Sustainability takes center stage in 2025’s SMT production.

Eco-Friendly Soldering and Energy-Efficient Machines

- Lead-free solder with improved conductivity.

- Smart power systems that reduce idle energy use.

- Recyclable materials are used in PCB production.

9. Cloud-Based SMT Line Management

Centralized control, no matter where you are in the world? It’s now possible.

Centralized Monitoring and Control

- Secure dashboards allow you to track KPIs across multiple locations.

- Remote updates and process changes are streamlined.

- Built-in disaster recovery and backup systems.

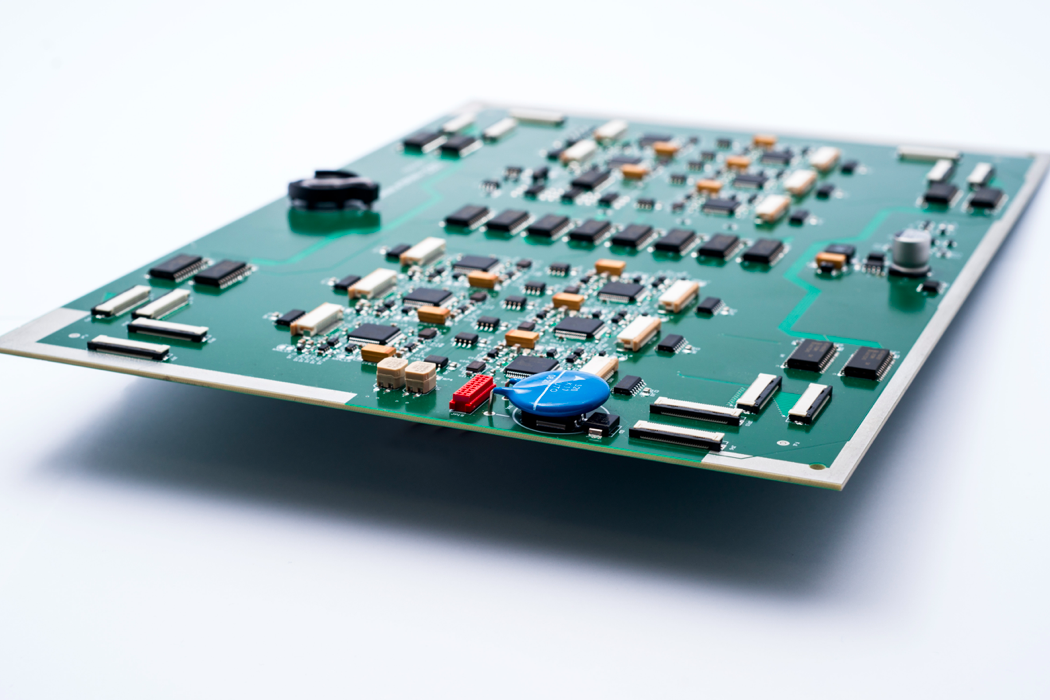

10. Advanced Materials and PCB Substrates

Materials in 2025 are stronger, lighter, and more conductive than ever before.

How Materials Are Evolving to Support Innovation

- Thermal-resistant substrates extend the lifespan of PCBs.

- Flexible PCBs are perfect for wearables and IoT devices.

- Enhanced copper and composite blends improve signal integrity.

FAQs

- What is SMT manufacturing?

SMT manufacturing involves attaching electronic components directly to the surface of printed circuit boards (PCBs).

- How is AI improving SMT manufacturing?

AI enhances inspection, predicts maintenance needs, and automates quality control, reducing human error and improving yield.

- What role does IoT play in SMT?

IoT enables machines and systems to communicate in real time, creating smarter production lines and predictive maintenance.

- Are these innovations cost-effective for small manufacturers?

Yes, many of these technologies offer scalable solutions for small and medium enterprises, providing solid ROI over time.

- What are the environmental benefits of modern SMT manufacturing?

New machines consume less energy, and eco-friendly materials reduce environmental impact, making SMT more sustainable.

- Is cloud-based SMT management secure?

Absolutely modern systems use end-to-end encryption and secure servers to protect sensitive production data.

Conclusion

The future of SMT manufacturing is here, and it’s nothing short of exciting. With advancements in AI, IoT, robotics, and sustainability, 2025 is setting a new standard for electronics production. Whether you are a startup or a global leader, these innovations are shaping a smarter, faster, and greener future.

Ready to optimize your SMT line? At Electronic Integration INC, we bring the future to your factory today.