About Us

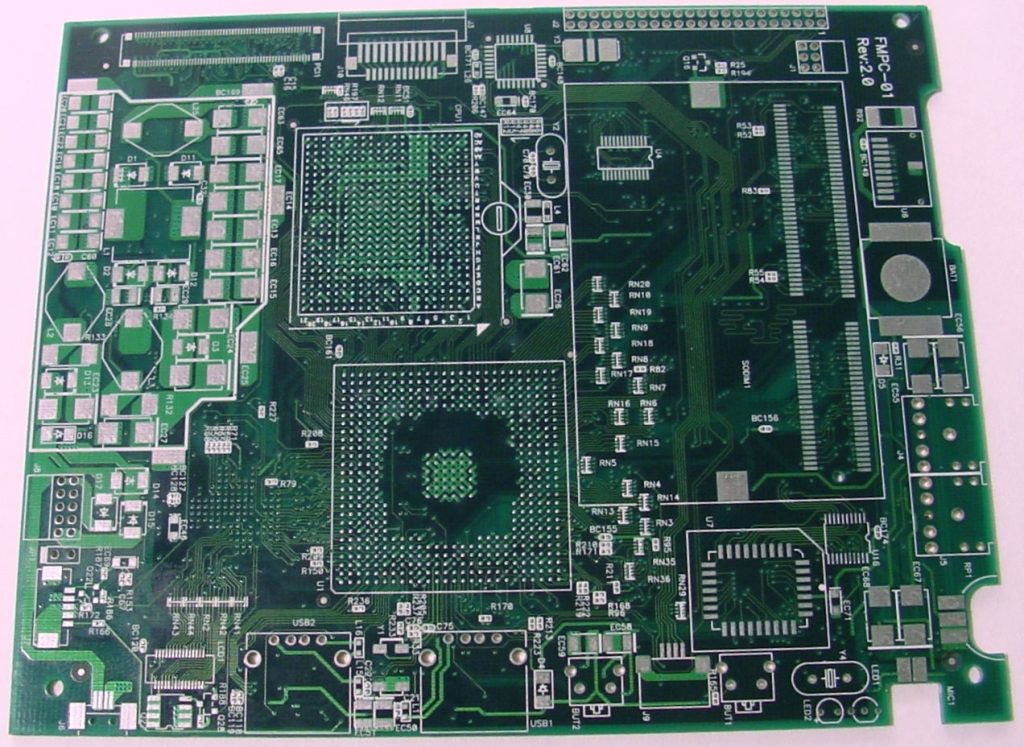

Our team consists of individuals who have decades of experience in PCB fabrication and pcb assemblies. These are highly motivated, dedicated and skilled professionals.

Sona Sitapara our President has decades of experience in the fabrication of PCB.

Ethan Monelasy who runs the Assembly plant has decades of hands on experience with PCB Assembly Manufacturing

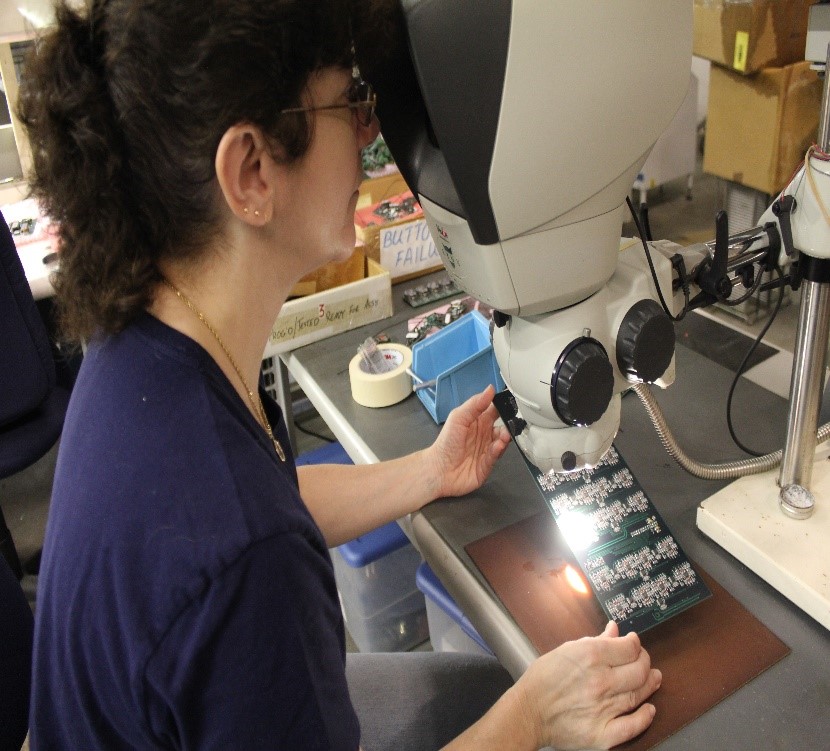

Diane Our QC Manager has vast experience in quality control and soldering experience. IPC-A-610 Class II and III

From management personnel to assembly operators, each employee is focused on exceeding customer requirements. Our automated equipments from stencil printers, surface mount pick and place machines, reflow ovens, selective soldering machines and rework stations are all geared to support a wide range of leaded and lead-free assembly requirements. Our manufacturing operations and processes are supported by ISO 9001-2015 procedures and documentation.

Our Summary of Services Include

- Support for PCB Layout & Design

- Engineering DFM and DFA

- Surface Mount and thru Hole Assemblies including 0201, Micro BGA to largest BGA. Complex densely populated double sided assemblies

- Prototype runs from 1 to 10 assemblies

- Low volume and Preproduction runs

- Production runs

- Fast turn around

- Full Turnkey

- Automated AOI and X-Ray inspecion

- Subassembly and Box build

- Full System Integration

- Functional Testing

- BGA rework and repair

- Supply Chain Management

- Conformal Coating

- Fulfillment and Packaging Services.

WHY CHOOSE EII

Besides being ISO 9001:2015 certified our biggest niche is all PCB fabrication and assembly is done in-house under the same management. This gives us

Flexibility:

For implementing product changes. Any last minute’s changes in the product layout or design can be implemented with the least amount of loss of time and manpower. No need to go thru multiple channels avoiding the likelihood of errors. This in turn also leads to an increase in market response.

Improved Quality:

Working in-house our team can give a lot of personal attention to detail as well as keep track of your product. We have complete and better control over the production processes. Production control leads to better quality.

Lower Management Cost:

Streamlining our processes have lead to low overhead cost. The outcome is a positive customer experience.

Environmental:

Electronic Integration Inc. operates with constant consideration for the environment by

• Optimizing the use of energy

• Ensuring the efficient use of materials.

• Encouraging re-use and recycling

Our Program Manager’s job is to help oversee and co-ordinate the various projects, and other strategic initiatives within our company.

He is a single point of contact for the customer and has a significant say in the operations of an order. He reflects a high level of experience in all stages of manufacturing. His role is hands-on and requires strong leadership and people skills. He is responsible for customer satisfaction and any issues that come up in the production. From the start of a project, his functions are

- Setting up tools and standards for managing the program.

- Evaluate customer BOM/AVL & provide a quote.

- Check customer Inventory.

- Strategize component procurement whether domestic or international.

- Generate customer order Confirmation and enter the order into the system. Generate our digital Job Traveler to manages all aspects of the product build.

We strive for zero defect product. . We have in place policies, standards and procedures to reach this goal. Our Quality Control is built into each phase of the manufacturing cycle to prevent unnecessary repair or rework.

Electronic Integration has in place work instructions and procedures to ensure that the product meets the customer’s specifications as well as a high level of process repeatability. Documented processes and procedures are used to improve standard and non standard requirements.

We constantly review and rank every supplier periodically to ensure a materials are provided as per our customers requirements.

We apply Design For Manufacturability and DFT guidelines to customer’s requirements before proceeding with an acceptance of order so as to confirm customers specifications, delivery and other technical and business requisites can be met.

Electronic Integration Inc periodically conducts surveys to gather feedback both positive and negative from our customers. This in turn helps us to make improvements.

We are ISO 9001:2015 certified and our inspectors and solderers are trained and certified per IPC 610 Class 2 and 3 standards. During the production cycle different inspection methods will be performed based on customer requirements They are Visual Inspection, Xray Inspection , AOI Inspection and In circuit Testing.

PROGRAM MANAGEMENT

Our Program Manager’s job is to help oversee and coordinate the various projects, and other strategic initiatives within our company.

He is a single point of contact for the customer and has significant say in the operations of an order. He reflects a high level of experience in all stages of manufacturing. His role is hands-on and requires strong leadership and people skills. He is responsible for customer satisfactions and any issues that come up in the production. From the start of a projects his functions are

- Setting up tools and standards for managing the program;

- Evaluate customer BOM/AVL & provide a quote

- Check customer Inventory

- Strategize component procurement whether domestic or international.

- Generate customer order Confirmation and enter the order into the system. Generate our digital Job Traveler to manages all aspects of the product build.

- Track and Expedite orders thru the manufacturing process. Setting and tracking change control procedures if any. This also helps in fine tuning the manufacturing process.

- Evaluate our process to eliminate waste and Eco implementation

- Planning, tracking, and reporting on outputs and outcomes

- Customer Satisfaction Will also constantly update the customer on the status of their jobs especially if there are unexpected delays. Our communication with our customer is always top priority.

- Cross-project interdependency management

- Strategic overview and reporting on all programs to senior management.

All orders we accept are subject to our terms and conditions unless otherwise specifically agreed to in writing by Electronic Integration Inc. herein referred to as EII. These terms and conditions supersede all others – even if yours say they supersede ours.